Soldering Pallet Materials

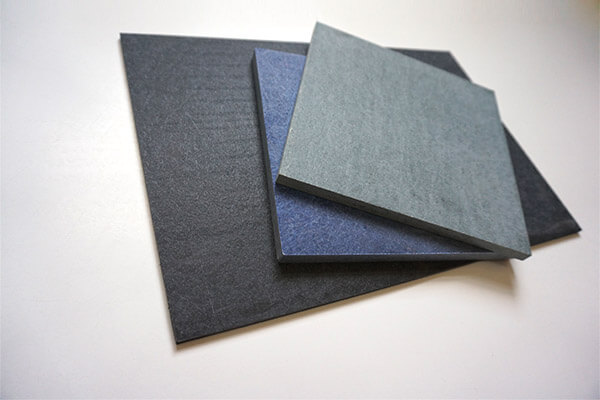

BETRONIC FM

BETRONIC FM is a composite material which is made by fiberglass reinforcement and thermosetting resin.

Application

BETRONIC FM is applicable to wave and reflow solder pallet, selective soldering, electronic components automatic cartridge, SMT surface mount technology and online testing jig.

Availability

Thickness: 3 mm – 120 mm

Dimension: 1020 x 1220 mm, 1220 x 2440 mm

Color: Black, Grey, Blue

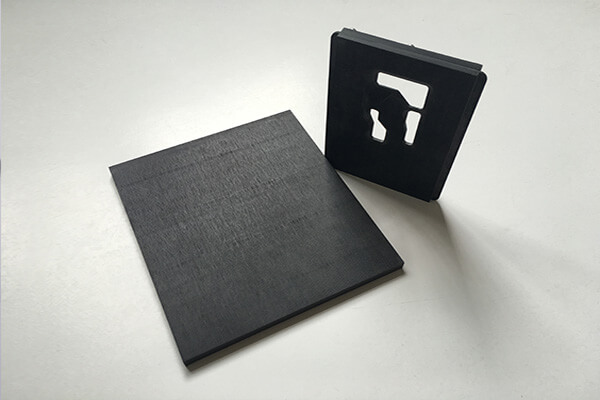

BETRONIC FC

BETRONIC FC is a kind of Lead Free composite material which is made by fiberglass reinforcement and thermosetting resin resin.

Application

BETRONIC FC is applicable to the lead free process, e.g. wave and reflow solder pallet, selective soldering, electronic components automatic cartridge, SMT surface mount technology and online testing jig.

Availability

Thickness: 3 mm – 120 mm

Dimension: 1020 x 1220 mm, 1220 x 2440 mm

Color: Black

FAQs

Frequently Asked Questions

What are the main allications of BETRONIC Materials?

BETRONIC Materials mainly apply to for Surface Mount Technology (SMT), assembling and mounting technology.

- Surface Mount Carriers

- Wave Solder Pallets

- Reflow Fixtures

- Selective Solder Fixtures

- In-circuit test (ICT)

- Screen Printing

What is the minimum thickness of the wall and base that can be machined?

0.8mm wall and floor thickness, if it the machined area is large enough, then do not recommend going down this thin.

What are typical RPM and feed-rates for cutting Betronic Materials

This is dependant on the machine tool you are using and will depend on the desired tool life vs production speed but typical settings are as follows:

8000 RPM maximum spindle speed and a typical speed of 7500 RPM.

For a 6 mm tool use a feed rate of 1,200 mm/min.Is it necessary to apply refrigerant or coolant while cutting the material?

Use coolant mainly to keep the dust down. Material can also be cutted without coolant but a vacuum or water is required to remove the dust.

What is the lifecycle of BETRONIC?

Lifecycle of BETRONIC is typically 10,000 cycles, affected by impact of heating and cooling conditions.

Want to Discuss Your Materials Solution ?

You can get the information below shortly. Our team will reply shortly.

- Materials Solutions

- 1st hand pricing

- One-stop supply

- Details on order minimums

- Delivery timelines

- Sample Availability