Welding is a general term and usually refers to a specific type of welding, such as gas welding, resistance welding, electric arc welding, induction welding, or laser welding.

Welding can be subdivided into braze welding and soldering. For both processes, a filling material is used which has a melting point below the melting point of the two workpieces that need to be connected. If the melting point of the filling material is below 427 °C (800 °F) we call that soft soldering. If the melting point of the filling material is at or above 427 °C (800 °F) we call that brazing.

To make it easier, the filling material is often mentioned alongside the method used. For instance, copper brazing is obviously used for braze welding, while tin solder and lead solder are used for soft soldering.

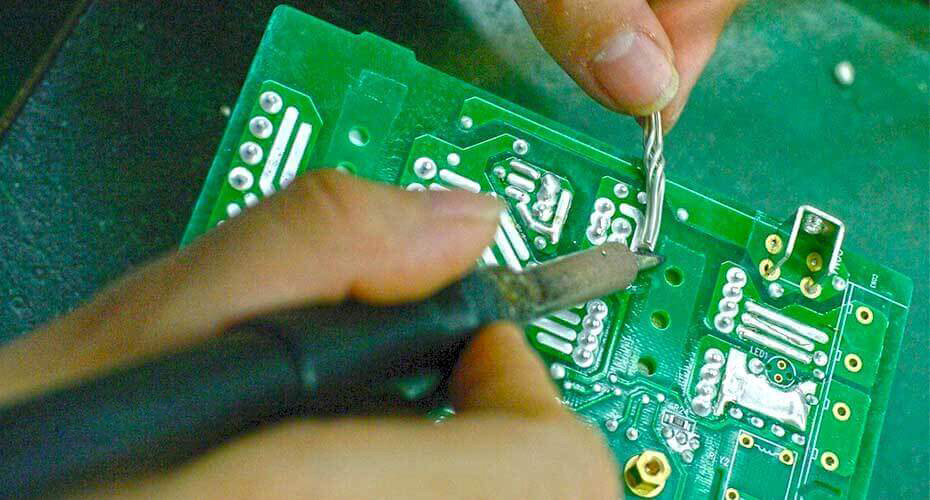

To sum it up, in the SMT industry, iron soldering, reflow soldering, and wave soldering are all forms of soldering. Only a few special welding posts will be used, for welding plastic packaging equipment, for instance.

Welding battery packs to a PCA manually is actually hand soldering. The solder spot on a PCA is called a solder joint, not a weld joint.